Semi-automatic Battery Cells Flatting Machine for 4680 and 32140 Tabless Cell

AOAO-RP-QJR46 tabless battery cell flatting machine utilizes rotary mechanisms to flatten the electrode

Brand:AOAO

Item No.:AOAO-RP-QJR46

Order(Moq):1

Payment:L/C,T/T

Product Origin:China

Shipping Port:XIAMEN

Semi-automatic Battery Cells Flatting Machine for 4680 and 32140 Tabless Cell

AOAO-RP-QJR46 tabless battery cell flatting machine utilizes rotary mechanisms to flatten the electrode

Specifications

Device functions and principles describes

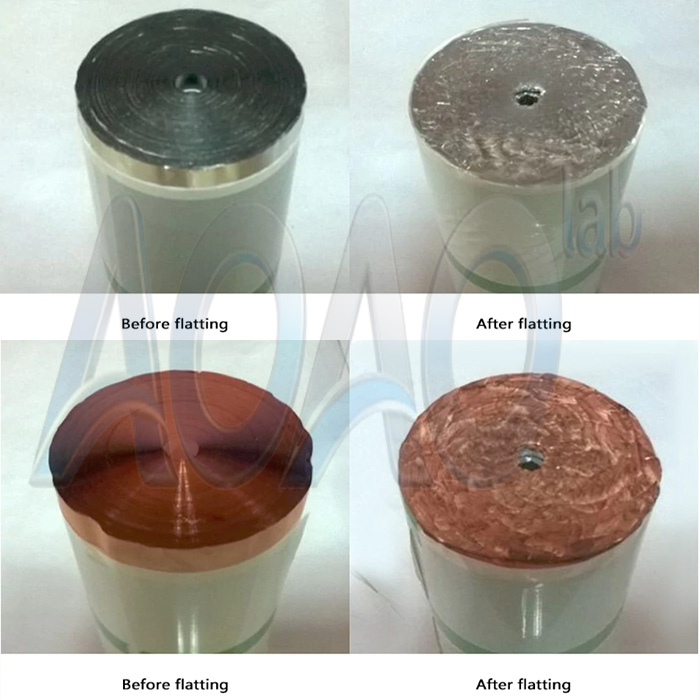

This AOAO-RP-QJR46 Tabless Battery Cell Flatting Machine is mainly used for power cylindrical lithium battery tab shaping. The working process is as follows: manually place the cell on the cell jig, click start, the jig automatically clamp the cell; two side shaping fixture starts to work, the servo motor starts, drives the tab shaping fixture at both ends to rotate, one side turns positive, the other side reverses, and the shaping fixture does slow feed, and the inner roller of the shaping fixture rotates under the battery cell contact surface friction, so that the battery cell can be compressed and formed to ensure the flat end face until the set length of the battery shaping is completed.(The attached figure shows the comparison between before and after shaping)

Equipment operation flow

Feeding the cell→cell positioning→flatting each side of cell→Automatic transposition→after flatting, discharge to the follow line→Manual receiving

Main component composition

· Transmission mechanism: 2 sets, It is controlled by servo motor and driven by synchronous belt.

· Positioning mechanism: 1 set, It is composed of cylinder and positioning sensor.

· Flatting head: 2 sets,It is composed of flatting head, synchronous transmission mechanism, electric module and positioning sensor.

· Electrical control system: It is composed of PLC, touch screen, detection sensor, relay, button and other control components.

· Machine body: Structural steel square tube, Platform: Structural steel plates, nickel-plated or collared, Machine cover: Aluminum alloy frame, transparent PVC plate.

Equipment technical parameter

· The qualified rate of the product:99%(It only refers to product obsolescence due to equipment problems)

· Capacity per unit/Speed(Single machine):≥15PPM(It varies slightly according to the material process)

· Operation rate of equipment: ≥95%(A fault caused only by the equipment)

· Equipment electrical:Voltage 220V 50Hz; Voltage fluctuation less than ±10%; Equipment power: 2KW

· Air source requirement:≥0.6Mpa(Provided by customer)

· Compressed air: Pressure 0.5-0.7MPa, flow 100 L/min

· Machine design should achieve excellent man-machine engineering performance

· Machine structure materials preferred aluminum and stainless steel or electroplating corrosion resistant

Spare parts list delivered with the device

Serial number | Device name | Unit | Quantity | Remarks |

1 | Solenoid valve | pcs | 2 | AirTAC |

2 | Optical fiber | pcs | 2 | Panasonic |

3 | Other homemade parts (normal wear and tear) | Free within 1 year | ||

4 | Magnetic switch | pcs | 4 | AirTAC |

Product Display

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China