Large Cylindrical Tabless Battery Jelly Roll Flattening Machine

The AOAO-GRP50320 Large Cylindrical Tabless Battery Jelly Roll Flattening Machine is designed for precision

Brand:AOAO

Item No.:AOAO-GRP50320

Order(Moq):1

Payment:L/C,T/T

Product Origin:China

Shipping Port:XIAMEN

Large Cylindrical Tabless Battery Jelly Roll Flattening Machine

Large Cylindrical Tabless Battery Jelly Roll Flattening Machine for Lithium-Ion Power Cell Manufacturing

Specifications

Product Introduction

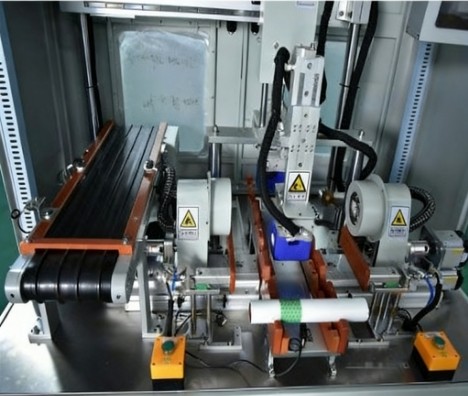

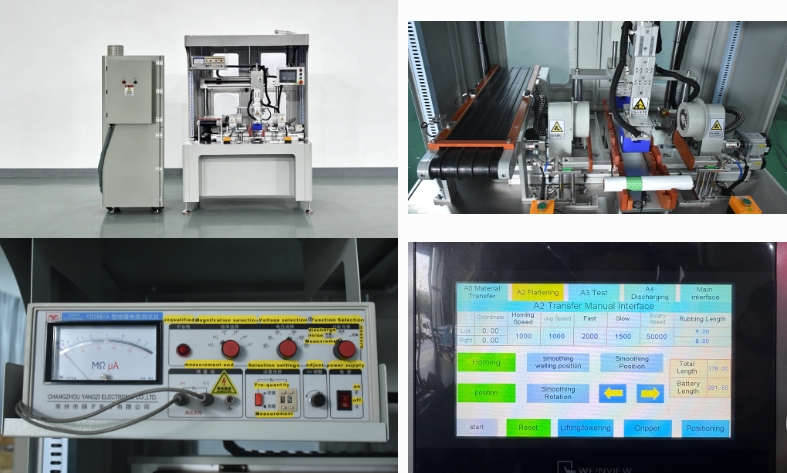

The AOAO-GRP50320 Large Cylindrical Tabless Battery Jelly Roll Flattening Machine is designed for precision flattening and forming of current collectors in tabless (full-tab design) cylindrical lithium-ion power cells.

By integrating servo-driven rotary flattening,ultrasonic-assisted forming, and controlled axial compression, the machine ensures flat cell end faces, uniform current-collector geometry, and high process consistency before welding and assembly.

This equipment is widely applied in tabless cylindrical power battery production lines, where electrical performance, structural stability, and manufacturing yield are critical.

Product Description

This machine is specifically developed for jelly roll flattening and current-collector forming in large cylindrical tabless lithium-ion batteries. During operation, the jelly roll is manually placed into the fixture and automatically clamped. Dual-side servo-controlled flattening heads rotate synchronously to evenly form the tabless current collectors while maintaining stable axial positioning.

An ultrasonic-assisted forming mechanism works in coordination with the rotary flattening heads, enabling slow and controlled feeding during compression. This process minimizes mechanical stress and ensures flat, uniform end surfaces, which is essential for reliable laser welding and electrical contact in tabless cylindrical cells.

The machine integrates dust extraction and in-process HI-POT insulation testing, allowing real-time quality control during the flattening process. Once the preset forming length is reached, the jelly roll is automatically transferred by a robotic handler to the downstream conveyor line.

This equipment is suitable for both pilot lines and mass production of tabless cylindrical power cells, offering high stability and consistent output.

Working Process

● Jelly roll loading

● Jelly roll positioning

● Dual-end servo rotary flattening of tabless current collectors

● Automatic station change

● Robotic unloading to conveyor line

● HI-POT insulation testing

● Manual collection

Main Components

● Drive System

Two servo-driven transmission units with synchronous belt mechanisms ensure precise and stable rotary motion.

● Positioning System

A dedicated positioning module consisting of pneumatic cylinders and positioning sensors provides accurate jelly roll alignment.

● Flattening Heads

Two servo rotary flattening heads with synchronized transmission, motor modules, and positioning sensors, specifically designed for tabless current-collector forming.

● Electrical Control System

PLC-based control architecture with touchscreen HMI, detection sensors, relays, buttons, and safety interlocks.

● Machine Structure

Frame: structural steel square tubing

Platform: structural steel plate with nickel or chrome plating

Enclosure: aluminum alloy frame with transparent PVC panels

Technical Specifications

Product yield rate | ≥99%(Scrap caused only by equipment-related factors) |

Capacity / Speed (single machine) | ≥2 PPM(Depending on material and process conditions) |

Equipment uptime | ≥95%(Downtime caused only by equipment faults) |

Power supply | AC 220V, 50Hz |

Voltage fluctuation | ≤ ±10% |

Installed power | 2 kW |

Air supply requirement | ≥0.6 MPa (provided by customer) |

Compressed air | Pressure: 0.5–0.7 MPa |

Consumption | Approx. 100 L/min |

Design standard | Ergonomic operation and maintenance |

Construction materials: | Aluminum alloy, stainless steel, or corrosion-resistant electroplated components |

Key Advantages (Tabless-Focused)

● Purpose-built for large cylindrical tabless lithium-ion batteries

● Servo-controlled dual-end rotary flattening for uniform current-collector forming

● Ultrasonic-assisted process improves end-face flatness and consistency

● Integrated dust collection and HI-POT testing

● High yield and stable operation suitable for automated production lines

● Supports scalable tabless battery manufacturing from pilot to mass production

Applications

● Tabless cylindrical lithium-ion power battery production lines

● EV and hybrid vehicle battery cell manufacturing

● Energy storage system (ESS) battery production

● Advanced cylindrical cell R&D and pilot lines

Product Display

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China