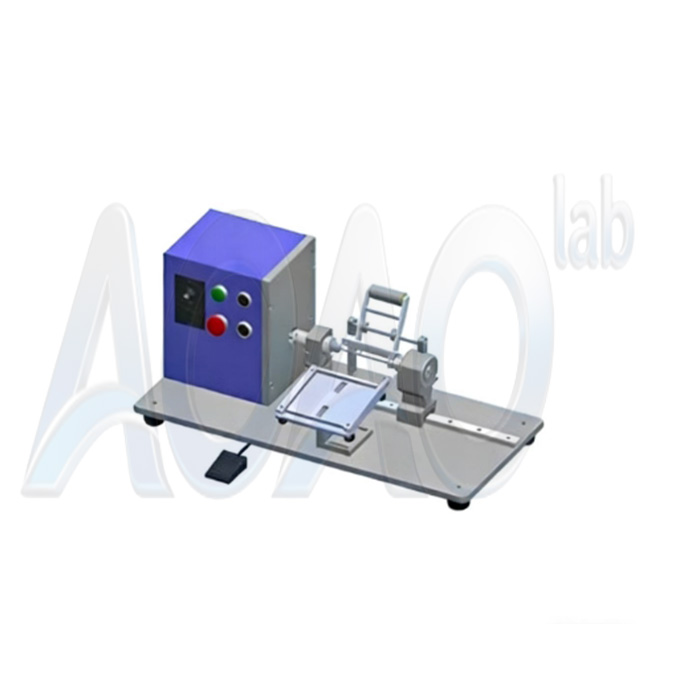

Semi-Auto Battery Winding Machine For 50320 Cylindrical Tabless Cell

This AOAO-SJR-50320 semi-automatic battery winding machine is designed for 50320 tabless cylindrical cells. Ideal for pilot lines and R&D lab-scale battery assembly.

Brand:AOAO

Item No.:AOAO-SJR-50320

Order(Moq):1

Payment:L/C,T/T

Product Origin:China

Shipping Port:XIAMEN

Semi-Auto Battery Winding Machine For 50320 Cylindrical Tabless Cell

This AOAO-SJR-50320 semi-automatic battery winding machine is designed for 50320 tabless cylindrical cells. Ideal for pilot lines and R&D lab-scale battery assembly.

This AOAO-SJR-50320 semi-automatic battery winding machine is designed for 50320 tabless cylindrical cells. Ideal for pilot lines and R&D lab-scale battery assembly.

The working process is as follows:

Manually guide the cathode and anode electrodes into the winding part, and separated stacking with the separator, and the winding will be carried out according to the requirements of the process, automatically attaching the termination tape, and the cell will automatically feed.

Function and Features

● Adopt single needle counter winding needle structure.

● Manual lead-in electrode, automatic winding, automatic change needle, automatic tape ending tape and automatic unloading.

● The adhesive tape adopts the horizontal paste (the tape is perpendicular to the tab), the adhesive is flat, and the adhesive position can be controlled accurately without tightening the cell; the adhesive is stable and reliable.

● winding needle speed was adjustable.

● Two rolls of separator active to unwinding, tension push switch control technology can adjust tension automatically during winding.

● It has a dust removal device.

● Separator outer pack end.

● The cell after winding without damage, core pulling and electrode dislocation phenomenon.

● Easy to operate,adjust and replace.

Working Process:

The machine meets the technical standard of the cylindrical lithium ion battery cell winding: the separator is completely wrapped the negative electrode, and the negative electrode is wrapped in the positive electrode.

The process flow is as follows:

● Separator pre winding: the length of pre winding separator can be saved by using the Tooth cutter technology.

● Winding the negative electrode: manually lead in the negative electrode into the winding part; winding the positive electrode: manually lead in the positive electrode into the winding part.

● Winding.

● Shift position.

● Cut off the separator , and stick termination tape and unloading.

Material specifications (unit: mm)

Material | Length | Width | Thickness | Inner diameter | Outer diameter |

Cathode electrode | 600~7000 | 178-318 | 0.1-0.2 | / | / |

Anode electrode | 600~7000 | 178-318 | 0.1-0.2 | / | / |

Separator | Roll material | 180-320 | 0.016-0.045 | 76.2 | 250 |

Termination tape | Roll material | 10-90 | 0.01-0.035 | 76.2 | 150 |

Technique Standard

Project | Project | Specification | Remark |

Basic specification

| Voltage | AC220V, 3KVA, 50HZ | |

Compressed air | 0.4-0.6MPa | ||

Equipment weight | about 1000kg | ||

Equipment size | 1850mm*1750mm*1650mm | Does not include the electrode material channel extension length . Unit :mm | |

Winding needle specification | ∮8.0mm-∮15mm | With one set for free, customized | |

Mechanical structure | Frame and panel | 1 set | |

Needle device | 1 set | ||

Electrode supply device | 2sets | ||

Separator supply device | 2sets | ||

Adhesive device | 1 set | ||

Control system | PLC | PANASONIC | Panasonnic AFRX-C60T |

Touch screen | Made in China | ||

Winding motor | Made in China | ||

Force motor | Made in China | ||

Sensor | Made in China | ||

Pneumatic components | Made in China | ||

Alarm system | Failure to stop | ||

Fault indication | Install program |

One-click reset | |

Attachment | Instruction operation | Instruction operation 1 set | |

Components | 1 set | Refer to the shipping list | |

Breakable parts and warranty time

No. | Name | Specification (mm) | Maintenance time | Remark |

1 | Winding machine | / | one year | Except for human factors (lifelong maintenance) |

2 | Gummed paper cutter | / | 3 months | |

3 | Winding needle | / | 3 months | Except for human factors |

4 | Thermocouple | / | 3 months | |

5 | Photoelectric magic eye | / | 6 months | crash and incoming oil without maintenance |

6 | Synchronous belt | / | 1Year | Machine oil, without maintenance |

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China