PVDF Powder Binder For Lithium Battery

AOAO-PVDF-210(Polyvinylidene fluoride ) binder is for mixing together with cathode powder to prepare Lithium battery electrode.

Brand:AOAO NEW ENERGY

Item No.:AOAO-PVDF-210

Order(Moq):1 bag

Payment:L/C,T/T

Product Origin:China

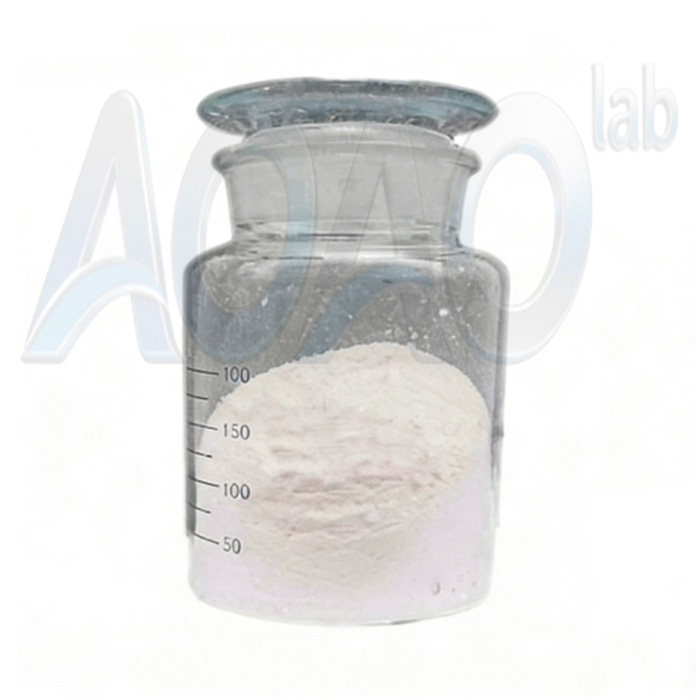

Color:white

Shipping Port:XIAMEN

PVDF Powder Binder For Lithium Battery

AOAO-PVDF-210(Polyvinylidene fluoride ) binder is for mixing together with cathode powder to prepare Lithium battery electrode.

Polyvinylidene fluoride(pvdf) powder as litium battery binder

SPECIFICATIONS

This P210 PVDF binder is a high-viscosity grade polyvinylidene fluoride homopolymer, which contains polar functional groups in the molecule, which can enhance the force between polymer molecules, active materials and metal electrodes, improve adhesion performance and corrosion resistance in electrolyte, it is especially suitable for the application of lithium iron phosphate and ternary material system in the electric vehicle industry.

It can effectively reduce the amount of formula used, reduce the DC internal resistance of the battery, improve the energy density and charge and discharge performance of the battery, and effectively increase the capacity retention rate of the battery during the cycle, thereby meeting the needs of the automotive industry.

Conventional | ||

Feature | Copolymer, high viscosity | |

Application | Battery binder, lithium iron phosphate, ternary system | |

Appearance | White powder | Test method |

Items | Typical value | |

FL2100 | ||

Physical properties | ||

Density(g/cc) | 1.77~1.79 | ASTM D792 |

Particle size (μm) (D50) | ≤110 | ISO 22412 |

Water content (%) (Time 24 hr) | ≤0.10 | ISO 62 |

Dissolution characteristics | ||

Rotational viscosity (cps) | 5,000~8,000 | 0.8gPVDF:9.2g NMP, Rotor 3, 25℃ |

Molecular properties | ||

Molecular weight (Da) | 1,100,000~1,350,000 | GPC,DMF,ISO 16014 |

Intrinsic viscosity (dl/g) | 3.1~3.6 | 30℃,DMAC |

The molecular weight distribution | 2.0~3.0 | GPC,DMF,ISO 16014 |

Thermal performance | ||

Melting point (℃) | 160~163 | ASTM D3418 |

Crystallization temperature (DSC peak) (℃) | 130~140 | ASTM D3418 |

Glass transition temperature, Tg (℃) | -40.0 | ASTM E1356 |

Decomposition temperature (℃) | 350 | 1% wt. loss / in air |

Heat of crystallization (J/g) | 36.0~45.0 | ASTM D3417 |

Heat of fusion (J/g) | 40.0~50.0 | ASTM D3417 |

Process safety instructions

1) This product should be processed below 260℃ to avoid the generation of toxic gas.

2) PVDF has good flame retardant and smoke suppression properties, however, when encountering a fire, it will release toxic hydrogen fluoride gas and fluorocarbons.

3) Operators should pay attention to personal protection during processing and use.

Packaging and storage

Packed in polyethylene plastic bags, then put them into cardboard drums, each with a net weight of 25Kg, and store them in a clean, cool and dry place.

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China