Auto Battery Electrode Winding Machine For 26650 Cells

This AOAO-AWM-26650-W auto battery electrode winding machine is suitable for 26650 lithium-ion cylindrical cell winding

Brand:AOAO NEW ENERGY

Item No.:AOAO-AWM-26650-W

Order(Moq):1

Payment:L/C,T/T

Product Origin:China

Shipping Port:xiamen

Auto Battery Electrode Winding Machine For 26650 Cells

SPECIFICATIONS

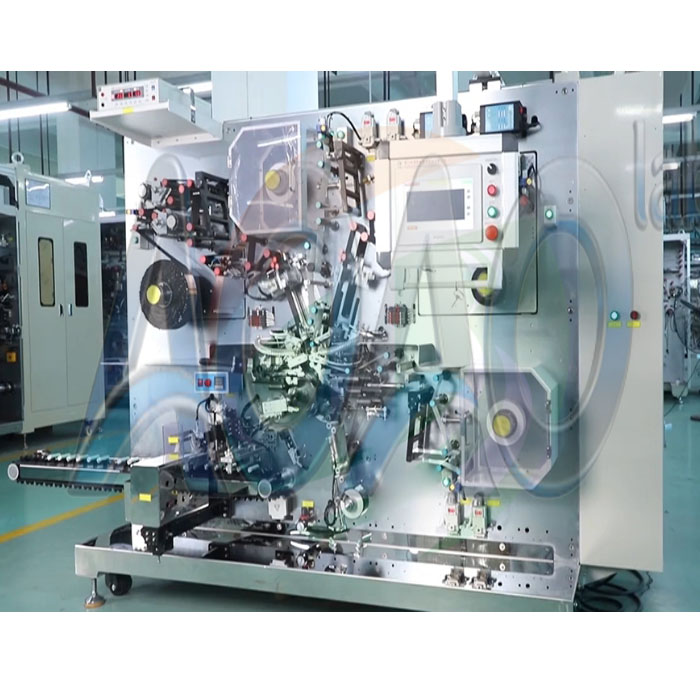

This auto battery electrode winding machine winds lithium-ion battery components (cathode electrode, anode electrode, and separator) into cells after processing them through mechanisms including dust removal, tension control, quality inspection, length measurement, running alignment, and static elimination. After cell formation, the process includes hot needle piercing, cathode tab welding and short-circuit testing, rejection of defective cells, and output via conveyor belt.

1. Mandrel feeding/retracting and direction change are fully cam-controlled for stability, high efficiency, and low failure rate.

2. The electrode employs three-stage alignment control: unwinding alignment, process alignment, and pre-winding alignment to ensure product quality.

3. Equipped with cathode tab welding.

Process Flow:

Upper Separator Unwinding (Alignment) → Tension Control → Static Elimination

Lower Separator Unwinding (Alignment) → Tension Control → Static Elimination

Cathode Electrode Unwinding (Alignment) → Dust Removal → Tension Control → Length Measurement → Process Alignment → Feeding & Cutting

Anode Electrode Unwinding (Alignment) → Dust Removal → Tension Control → Length Measurement → Process Alignment → Feeding & Cutting

Winding Cell with Termination Tape → Hot Needle Piercing (Optional) → Short-Circuit Test → Discharge & Conveying

Material specifications requirements

Name | Rolls | W (mm) | T(um) | L(mm) for single cell | Maxdiameter of material (mm) | Inner diameter of material roll (mm) |

Cathode | 1 | 55-65 | 80-180 | 100-2000 | Φ450 | Φ76.2 |

Anode | 1 | 55-65 | 80-180 | 100-2000 | Φ450 | Φ76.2 |

Separator | 2 | 55-67 | 12-35 | Φ300 | Φ76.2 | |

Termination tape | 1 | 25-60 | 20-60 | Φ200 | Φ76.2 |

Winding Method:

Adopts a three-mandrel, three-station winding system.

Mandrel Diameter:Ø3.5–Ø8.0 (or customer-specified)

Winding Diameter:Ø20–Ø26mm (for 26-series cells)

Number of Tabs:1 or 2 tabs (cathode or anode)

Tab Protrusion Length:8–25mm

Winding Precision:

Cathode-to-Anode Electrode Alignment: ±0.3mm

Electrode-to-Separator Alignment: ±0.3mm

Three-Stage Alignment Control for Electrodes (cathode/anode):

1) Unwinding alignment

2) Process alignment

3) Pre-winding alignment

Two Separator Layers Alignment: ±0.5mm

Production Capability:

For 26650(18650, 21700) cells: Production speed of 15 PPM

Operational Efficiency≥95%

Operational Efficiency = [Total Production Quantity / (Machine Runtime–Necessary Deduction Time)×Theoretical Production Speed]×100%*

Necessary Deduction Time: Downtime caused by non-equipment factors (e.g., material changeover, splice joining, production preparation).

Yield Rate≥98%

Yield Rate = [Total Good Products / (Total Production Quantity–Necessary Deduction Quantity)]×100%*

(Excludes defects caused by material factors)

Necessary Deduction Quantity: Defective products caused by non-equipment factors (e.g., poor splicing, electrode length deviation, missing tabs).

Equipment Technical Specifications

Power Supply: Single-phase AC220V±10%, 50Hz

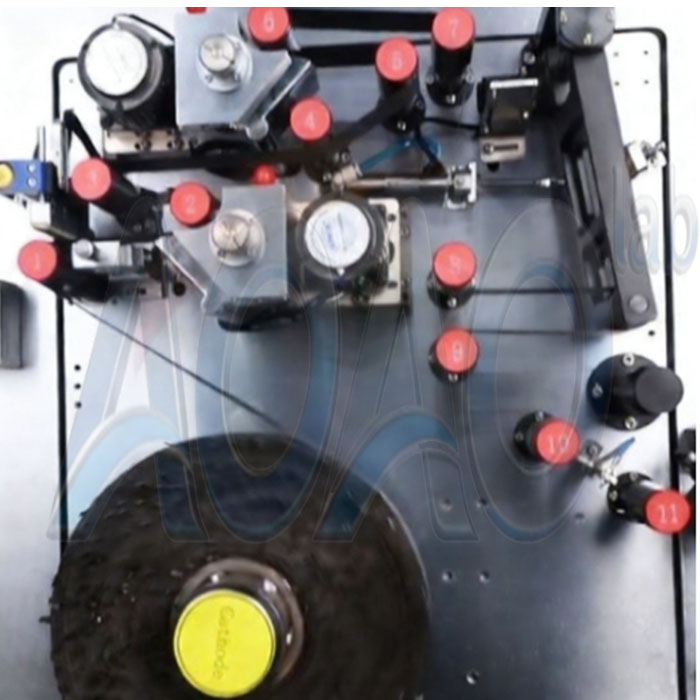

Pneumatic Supply: 0.5-0.7MPa (Required flow rate: 60L/min)

Temperature, Humidity & Environmental Requirements

1) Environmental Requirements: (According to JIS B 3502-1997 Programmable Controllers - Equipment Requirements and Tests)

2) Ambient Operating Temperature: 0°C to 55°C

3) Prohibited in corrosive, flammable, or excessively dusty environments.

Overall Dimensions: Length 2850mm×Height 2050mm×Width 1800mm (Actual dimensions subject to final design)

Exterior Color: Silver Gray (Or customer-specified color; color sample required)

Weight: Approx. 3000Kg (≤750Kg/m²)

Power Consumption: 12 kW (running)

Noise Level:≤75 dB (Excluding dust collector fan)

PRODUCT DISPLAY

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China