Laser Welding Machine For Cylindrical Tabless Battery Current Collectors

This AOAO-ZFJ50320-3000 laser welding machine is designed for cylindrical tabless battery cells, specifically for precision welding

Brand:AOAO NEW ENERGY

Item No.:AOAO-ZFJ50320-3000

Order(Moq):1 set

Payment:L/C,T/T

Product Origin:China

Shipping Port:XIAMEN

Laser Welding Machine For Cylindrical Tabless Battery Current Collectors

SPECIFICATIONS

Product Overview

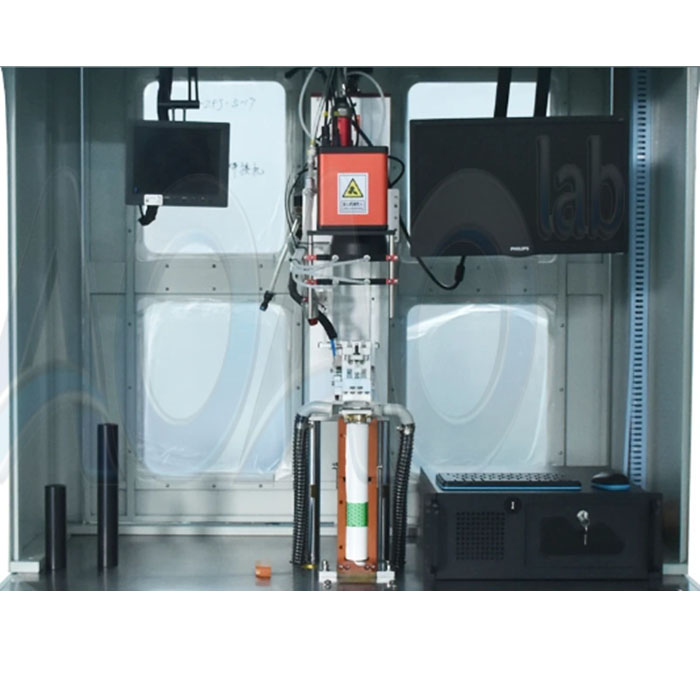

● This AOAO-ZFJ50320-3000 laser welding machine is designed for cylindrical tabless lithium-ion batteries, focusing on the high-precision welding of positive and negative current collectors.

● It is commonly used in battery production lines, pilot manufacturing, and laboratory-to-mass-production environments where welding consistency, yield rate, and process stability are critical.

● The system integrates fixture-based cell positioning, pneumatic pressing, and galvanometer laser welding, enabling accurate alignment and stable welding results for tabless battery structures.

Product Description

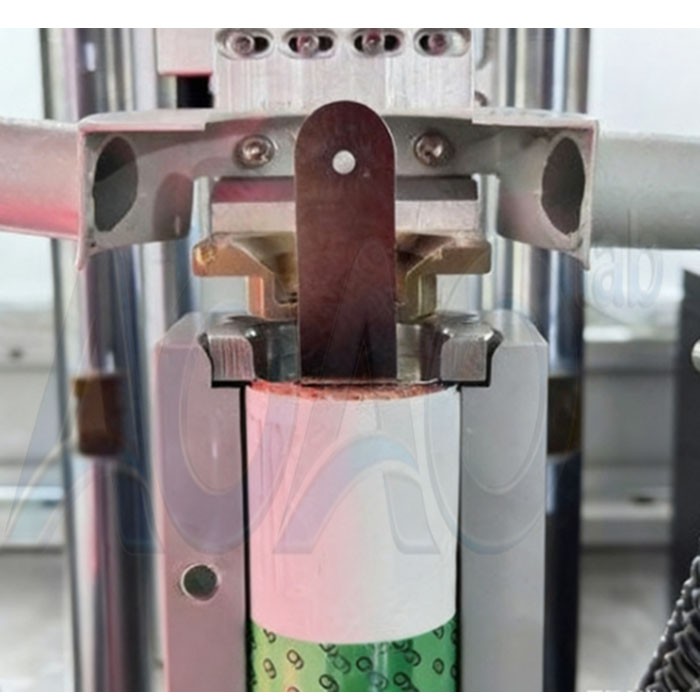

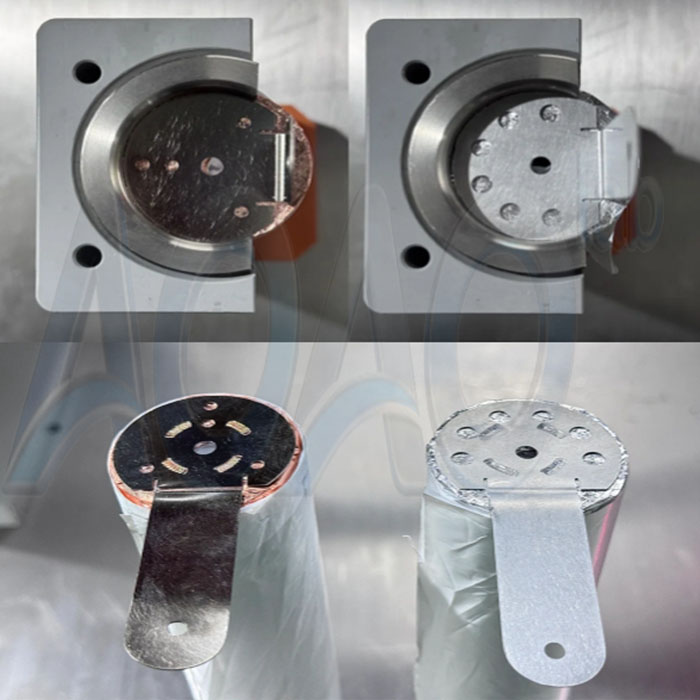

● The machine operates by securely positioning the flattened cylindrical battery cell using a precision fixture. After manual placement of the current collector, a pneumatic press head applies uniform pressure to stabilize the welding area. A galvo-controlled laser system then performs fast and precise welding on both the positive and negative current collectors.

● This equipment is engineered to support modern tabless battery designs, helping manufacturers improve electrical conductivity, reduce internal resistance, and maintain consistent welding quality throughout production.

With PLC-based control and an ergonomic mechanical design, the machine offers reliable operation, easy integration, and long-term production stability.

Working Principle & Process Flow

Working Principle:

● The machine combines mechanical positioning, pneumatic pressing, and laser energy control to achieve accurate and repeatable welding of battery current collectors.

Process Flow:

● Manually place the flattened cylindrical battery cell

● Manually place the current collector

● Pneumatic cylinder presses and fixes the collector

● Galvanometer laser system performs precision welding

● Positive and negative collectors are welded sequentially

● Dust extraction cleans the welding area

● Welded cell is manually transferred to the casing process

Main System Components:

● Cell Positioning System

Ensures accurate alignment of cylindrical cells using pneumatic cylinders and precision fixtures.

● Welding Press Head Assembly

Provides stable and uniform pressure through pneumatic cylinders, linear guides, and spring mechanisms.

● Laser Welding System

Includes a galvanometer scanner, positioning cylinders, and an industrial laser source for high-speed current collector welding.

● Electrical Control System

PLC controller, touchscreen HMI, sensors, relays, and safety components ensure precise process control and operational safety.

● Machine Frame & Enclosure

Constructed with structural steel, corrosion-resistant plated platforms, and aluminum alloy safety enclosures with transparent PVC panels.

Equipment technical parameters

● Product qualification rate: 99%(only referring to product scrapping caused by equipment reasons)

● Single equipment capacity/speed (single machine) :≥2PPM (slightly varying depending on the material process)

● Equipment utilization rate: ≥95% (Faults caused only by equipment)

● Electrical equipment: Voltage 380V 50Hz; The voltage fluctuation is less than ±10%

● Equipment power: 10KW

● Air source requirement: ≥0.6Mpa (provided by the customer)

● Compressed air: Pressure 0.5-0.7 MPa, usage 100 L/min

● The machine design should achieve excellent ergonomic performance

● The structural materials of the machine are preferred to be aluminum, stainless steel or electroplated for anti-corrosion

Typical Applications of the Laser Welding Machine

● Cylindrical tabless lithium-ion battery production

● Battery pilot production lines

● Laboratory-to-production scale-up

● Custom battery manufacturing solutions

● Advanced battery R&D welding processes

Key Advantages

● Designed specifically for tabless cylindrical battery structures

● High-precision laser welding of current collectors

● Stable welding quality with ≥99% yield rate

● Supports consistent production in battery manufacturing lines

● Suitable for both pilot lines and scalable production

● Easy integration into existing battery production systems

PRODUCT DISPLAY

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China