Lab Coater Coating Machine For Battery Research

Designed to meet the demands of next-generation material science, this system enables reproducible thin-film deposition under controlled high-temperature environments (up to 200°C).

Lab Coater coating machine For Sodium-Ion Battery Research

Product Overview

battery material Coatings (Li-ion, solid-state electrolytes)

Designed to meet the demands of next-generation material science, this system enables reproducible thin-film deposition under controlled high-temperature environments (up to 200°C).

Key Advantages

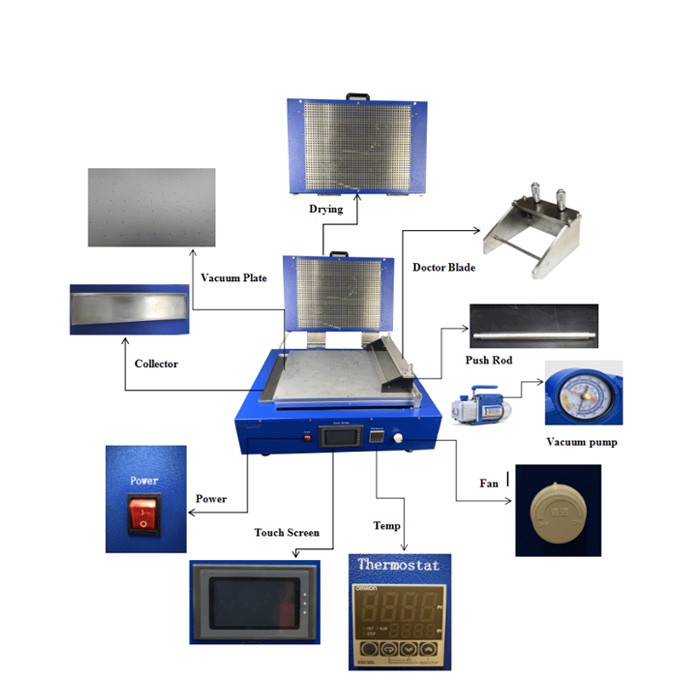

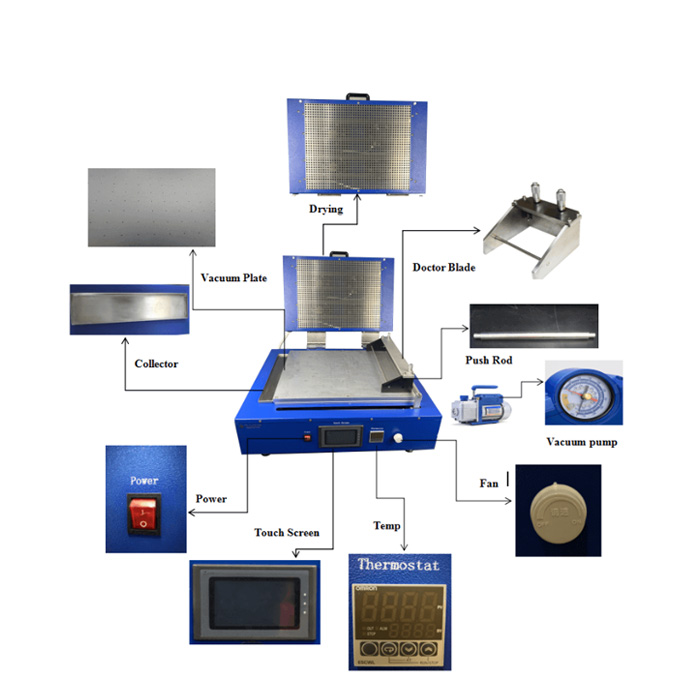

▸ Unrivaled Thermal Precision

Large-area heating with ±1°C accuracy ensures laboratory-grade temperature uniformity for reproducible results.

▸ Smart Speed Control

Motor-driven blade/rod coater with 0-120mm/s digitally adjustable speed (10mm/s resolution) enables optimal coating consistency.

▸ Deformation-Free Substrate Handling

Vacuum-aluminum holder with >20kPa adsorption force guarantees flat, distortion-free film deposition.

▸ Space-Optimized Design

Glove-box compatible compact footprint maximizes lab space utilization.

▸ Versatile Coating Capability

40µm-5mm thickness range (±3µm repeatability) supports

▸ Intuitive Operation

User-friendly PLC touchscreen allows single-touch presets for temperature, speed, and stroke parameters.

▸ Certified Reliability

CE-certified with IP54 protection grade ensures safe operation in demanding research environments.

Technical Specifications

Feature | TMH250 | TMH300 | TMH550 | Customizable |

Coating Area | 100×250mm | 200×300mm | 250×550mm | Tailored to Need |

Max Temperature | 200°C (±1°C) | 200°C (±1°C) | 200°C (±1°C) | 200°C (±1°C) |

Thickness Range | 40µm-5mm | 40µm-5mm | 40µm-5mm | 10µm Option |

Vacuum System | Built-in Oil-free Pump | Built-in Oil-free Pump | External Oil-free Pump | Built-in Oil-free Pump |

Power Requirements | 220V/110V | 220V/110V | 220V/110V | 220V/110V |

Machine Weight | 66kg | 80kg | 108kg | Custom |

Dimensions (L×W×H) | 570×410×420mm | 620×460×420mm | 810×510×420mm | Custom |

Workflow

Substrate Prep

Secure copper/aluminum foil on vacuum plate (activated via touchscreen).

Coating Phase

Dispense slurry → Auto-blade coating at preset speed (e.g., 60mm/s for LiFePO₄).

Drying

Cover with heated enclosure → Set time/temperature (RT-200°C).

Output

Retrieve defect-free coated film in <5 minutes.

Our Automatic Precision Coating Machine is engineered for cutting-edge research in high-temperature film formation, including:

✔ Uniform Thermal Control

✔ Precision Coating Technology

✔ Modular Flexibility

✔ Smart Operation

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

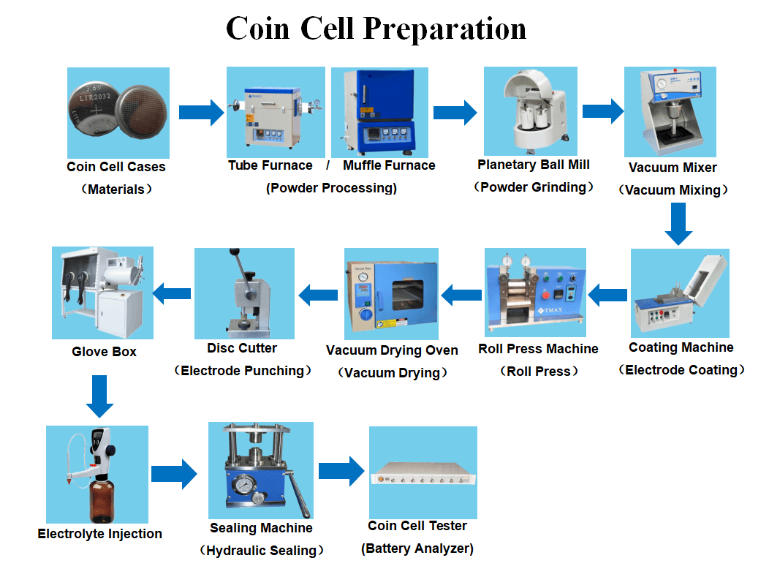

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China