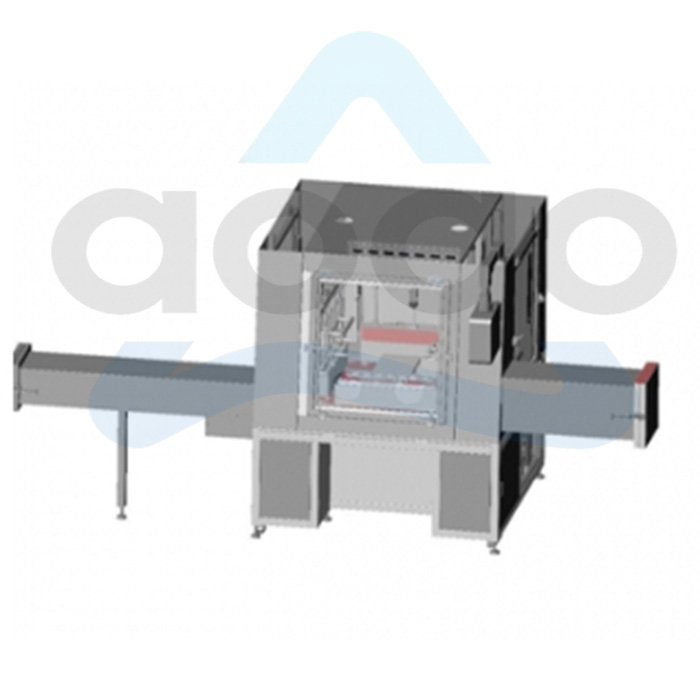

800*750 Sodium Ion Battery High Precision Rolling Press Machine

Model Number:AOAO-YK-800*750-L

Compliance:CE Certified

Warranty:One year limited warranty with lifetime technical support

Payment:T/T, Western Union, PayPal, Credit Card, Cash, Alipay, L/C etc.

Delivery Time:5 days

800*750 Sodium Ion Battery High Precision Rolling Press Machine

1、List of equipment specifications

No. | Equipment name | Equipment model | Remarks |

1 | High Precision Lithium Battery Rolling Press Machine | AOAO-YK-800*750-L | The effective rolling width is 200~680mm. |

1.1 Equipment composition and function

Main configuration of equipment

No. | Name | Place of Origin |

1. | Air switch | Schneider (France) |

2. | PLC | Siemens (Germany) |

3. | Touch screen | Smet (Taiwan) |

4 | Modular | Siemens (Germany) |

5. | Intermediate relay | Schneider (France) |

6. | Drive servo motor | Siemens (Germany) |

7 | Reducer | International Trade (China) |

8. | Memorial Gateway | Shaogang (China) |

9. | Bearing | Wafangdian (China) |

10. | Coupling | Zhengtong (China) |

11 | Hydraulic ram cylinder | Siemark (Germany) |

12. | Full automatic tension | PID closed loop control (self-made) |

13. | Deep groove ball bearing (machine head) | NSK (Japan) |

14. | Frequency converter | Rexroth (China) |

15. | Rectify deviation | Dongdeng (Guangzhou) |

2、Introduction to equipment principle

The traction of electrode is compacted to the predetermined thickness or the predetermined compaction density by the double action of pressure and the nip of the pressure roller, so that the lithium battery produced by the rolled pole piece can achieve the designed / predetermined volume energy density and battery performance.

No. | Project | Describe | Note |

1 | Suitable system | Continuous rolling process for positive and negative plates of lithium iron phosphate, lithium cobalt oxide, lithium manganate, lithium nickel cobalt manganese and other battery systems. | |

2 | Rolled substrate | Aluminum foil (10um-1.5mm), copper foil (6um-1.5mm), | |

3 | Rolling mode | Width: 200mm-750mm. | Motor drive position |

4 | working pressure | The two rollers are rolled up and down horizontally, and the drive is located on the right side of the feeding end. | |

5 | Equipment speed | Provided by constant pressure pump station, it is suitable for positive high pressure rolling and negative low pressure adjustment. | |

6 | control mode | Stepless adjustment, and the linear speed of the upper and lower rollers is equal. |

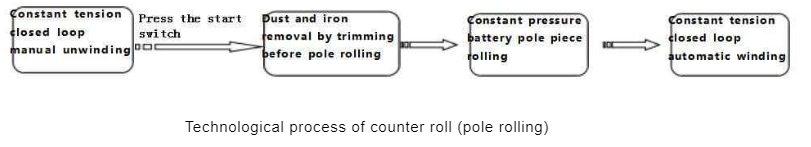

3、Equipment action sequence

4. Equipment composition and functional

Equipment component configuration

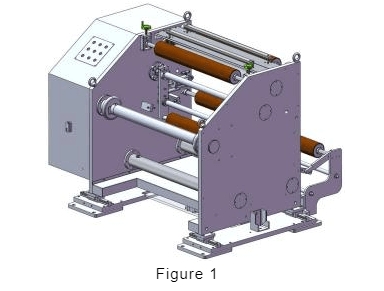

4.1 unwinding system (as shown in Figure 1)

No. | Project | Describe | Note |

1 | Discharging part | φ 76mmx750mm inflatable shaft unwinding, equipped with air gun | |

2 | Receiving platform | Pneumatic lifting of steel plate front receiving platform and pressing plate | |

3 | tension control | Swing roll type, low friction cylinder controls the tension, and the sensor detects and displays the tension | |

4 | Deviation correction system | Photoelectric deviation correction and linear guide rail (the maximum moving range is 100mm) | |

5 | Rectification execution | Dongdeng deviation correction actuator | |

6 | Sub control system | The discharging and receiving end is equipped with equipment sub control system and emergency stop (dynamic brake), pause and other buttons | |

7 | Iron removal before rolling | Electromagnetic pole piece iron removal device, magnetic force of magnetic rod 10000~12000 Gauss |

4.2 Trimming system before pole rolling (as shown in Figure 2)

No. | Item | Describe | Remarks |

1 | Knife feeding requirements | Pneumatic slitting blade (HRC ≥ 58). | |

2 | Cutting requirements | ¢ 150*50 bottom knife. | |

3 | Trimming speed | It can automatically match the rolling mill running line speed (i.e. synchronization, response time ≤ 10ms), and | |

4 | Scrap recycling | Can be adjusted separately; There is no material dropping and broken belt at the cutting edge. | |

5 | Trimming width | Automatic collection, equipped with receiving box. |

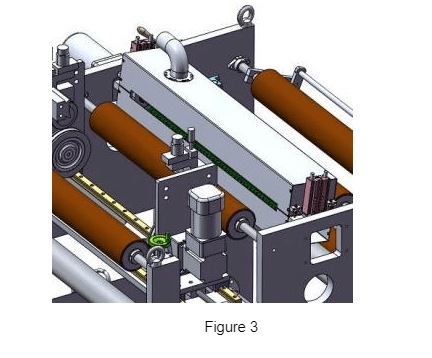

4.3 Dust removal system before pole pressing (as shown in Figure 3)

INQUIRY

CATEGORIES

- Battery Materials

- Sodium Ion Battery Production Li

- Solid State Battery Equipment

- Battery Production Line

- Coin Cell Lab Equipment

- Electrode Preparation

- Pouch Cell Assembly Equipment

- Cylindrical Cell Assembly Machin

- Prismatic Cell Assembly Machine

- Glove Box

- Lab Furnace

- Ball Mill for Lab

- Laboratory Equipment

- Lithium Battery Production Plant

- Battery Tester

- Press Machine

- Supercapacitor Equipment

- Prismatic Battery Pack Equipment

- 18650 Battery Pack Assembly Equi

- Cylindrical Battery Pack Machine

LATEST NEWS

CONTACT US

Contact: Lily Zhao

Phone: 15880250943

E-mail: Lily@aoaolab.com

Whatsapp:8615880250943

Add: No. 208, Binghu Erli Road, Haicang District, Xiamen city, China